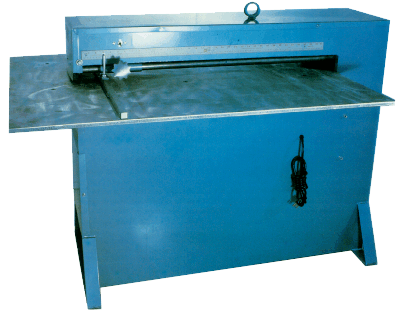

SINGLE SLITTER SPECIFICATIONS AND FEATURES

MAR-BEL ASSOCIATES and its predecessors have manufactured machinery for the laminate industry since 1958. The equipment has a well deserved reputation for reliability and customer support. For these reasons it is found in the quality control, research, or operations departments of such industry giants as FORMICA® Corporation, Ralph Wilson Plastics’ WILSONART® division, International Paper’s NEVAMAR® division and WESTVACO®. It is as easily found in two employee shops because of its versatility and value pricing. The MAR-BEL slitter is manufactured as originally configured by U.S. Patent #3,496,812. It is technically a die which punches out a 1/16″ kerf. The single slitting models are designed to provide their owner with maximum throughput of accurate, smooth-edged laminate product over the range of cutting widths allowed by the throat model selected. The machine will slit over a variety of thicknesses, easily slitting vertical or countertop grades without adjustment for the variation in material thickness.

FEATURES (Single Cut)

- FENCE – sturdy double slide-dual lockdown mechanism assures durable, accurate service (inset).

- DUSTFREE – 1/16″ kerf is disposed of through the chut

e utilizing a free floating extractor blade. This is a non-wear part that prevents the blade set from being “sprung” by kerf collection. - EFFICIENT – after the operator has properly aligned the fence, the machine will tirelessly slit your material to size, only requiring the operator to hold the material against extractor blade. This is a non-wear part that prevents the blade set from being “sprung” by kerf collection.

- COST EFFECTIVE – once “snapped in” on the machine’s operation, relatively unskilled labor can operate the slitter and free up saws for tasks they are better designed for. The MAR-BEL slitter owner will also experience noticeable economies in sharpening costs due to the unique cutting technique of the die used to slit the laminate, blade wear is minimal…..the quality of the cut will not gradually deteriorate as you can expect from the common aluminum shear (two blade) device. In addition, the three-bladed die won’t give you a beveled edge as shears tend tod

o as they dull. Expect fewer lineal feet when cutti ng metallics. The blades can normally be sharpened 4-7 times when serviced properly. Our renowned factory sharpening staff ensures that the blades are checked for sufficient OD and prompt in-house turnaround. All of the above spell substantial s avings in terms of sharpening costs and unneeded circular saw blades. - TOLERANCE – cut edges are specified to within 1/32″ or better of a straight edge if the operator properly holds the material to the fence. Different widths are slit with quick fence adjustments.

- OTHER TECHNICAL DATA – (Single Cut Slitters) 1/3hp totally enclosed fan cooled gear motor with in-line reducer, 110v, 60HZ split phase motor feed speed approximately 40 fpm • self-feeding • 1/2″ minimum cut

LS-1, LS-7, LS-12

TTLS-4, TTLS-7

DLS-26, DLS-36